IKBFU scientists have discovered that physical impact on amorphous ferromagnetic glass-coated wires during heat treatment — annealing — improves their magnetic properties. Such materials, due to their ability to rapidly change their magnetic properties, could be used to create protective magnetic tags and sensors. Therefore, new insights on how to effectively manipulate their properties will help expand their applications in engineering. The study was published in the journal Materials Research Bulletin.

Amorphous ferromagnetic glass-coated wires are promising composite materials due to their strength, corrosion resistance, biocompatibility, and controllable magnetic properties. The latter makes it possible to use them for manufacturing protective magnetic tags and magnetoelastic sensors — devices for converting physical impact (compression, tension, bending, pressure, etc.) into voltage or current.

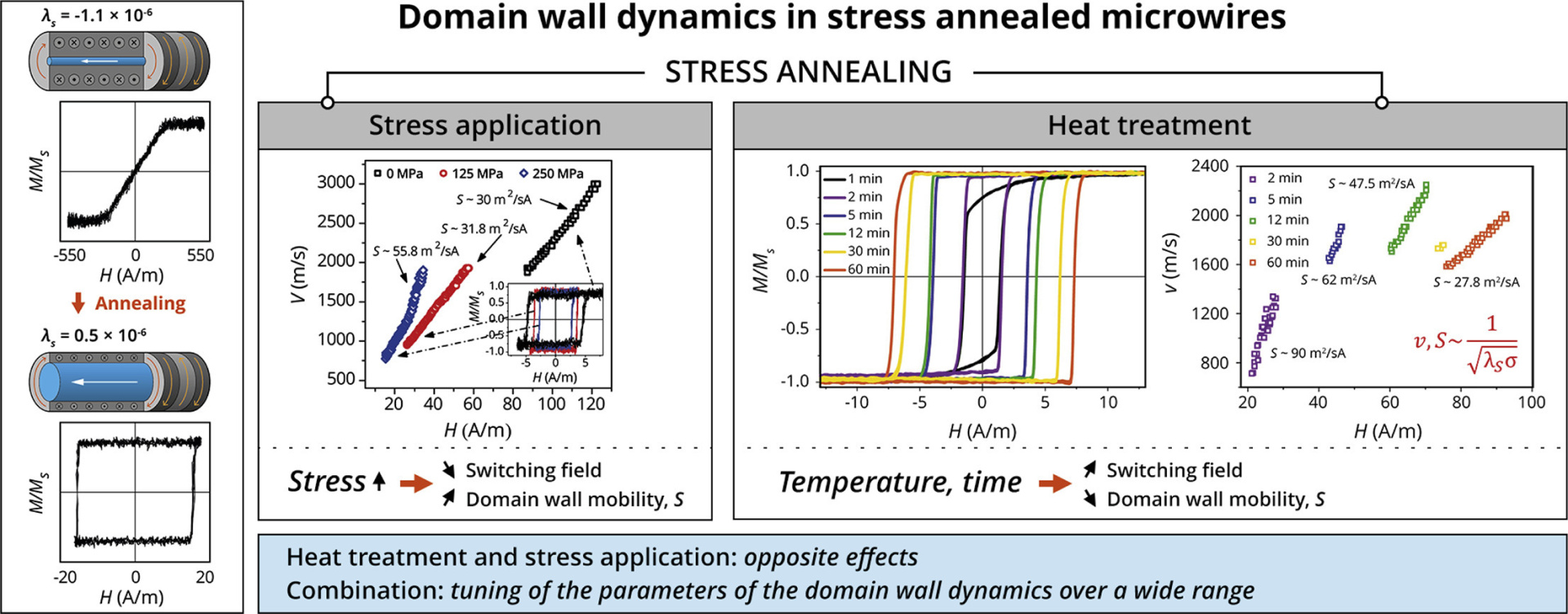

As test samples, the authors used glass-coated microwires with a cobalt, iron, nickel, boron, silicon, and molybdenum alloy core 24 micrometres in diameter (about half as thin as a human hair) and 10 centimetres long. As test samples, the authors used glass-coated microwires with a cobalt, iron, nickel, boron, silicon, and molybdenum alloy core 24 micrometres in diameter (about half as thin as a human hair) and 10 centimetres long. The microwires were placed in a muffle furnace heated to temperatures of 200, 300 or 350°C for varying lengths of time, from one minute to one hour. In addition to temperature, the researchers investigated the effect of physical stresses. For this purpose, weights were placed on some samples during annealing, which created a stress equal to the action of 125 megapascals (1,274 kilograms per square centimetre) or 250 megapascals (2,549 kilograms per square centimetre).

The experiment showed that the composite did not fracture under such stresses: both the glass coating and the metal core did not deform or deteriorate.

The scientists evaluated the magnetic properties of the microwires after annealing. They found that the rate at which the magnetic properties changed increased with the duration of annealing. However, annealing for more than 30 minutes caused this rate to decrease.

Additionally, the physical stresses experienced during annealing were associated with a reduction in the magnetic field strength needed to initiate changes in the microvire’s magnetic properties.

User profile for student

User profile for student

I give consent to the processing of the personal data provided, with Personal Data Processing Policy acquainted

Confirm consent